Allevi Blog

Allevi Author: Review of Bone Biofabrication Methods & Bioinks

- Updated on April 3, 2020

In this edition of the #AlleviAuthor series, our very own Director of Bioengineering, Taci Pereira, reviews state of the art bone biofabrication technologies for the Journal of 3D Printing in Medicine.

In the USA alone, 500,000 bone grafting procedures are performed annually, with musculoskeletal-related disabilities costing about $240 billion each year. In spite of the advancements over the past 20 years, scientists and engineers have been unable to provide a material that fulfills every characteristic needed for bone tissue to be physiologically relevant in clinical applications.

Pereira examines the six essential characteristics of bone biofabrication graft materials; osteoinduction, osteoconduction, osteointegration, biocompatibility, translatability, and growth factor necessity.

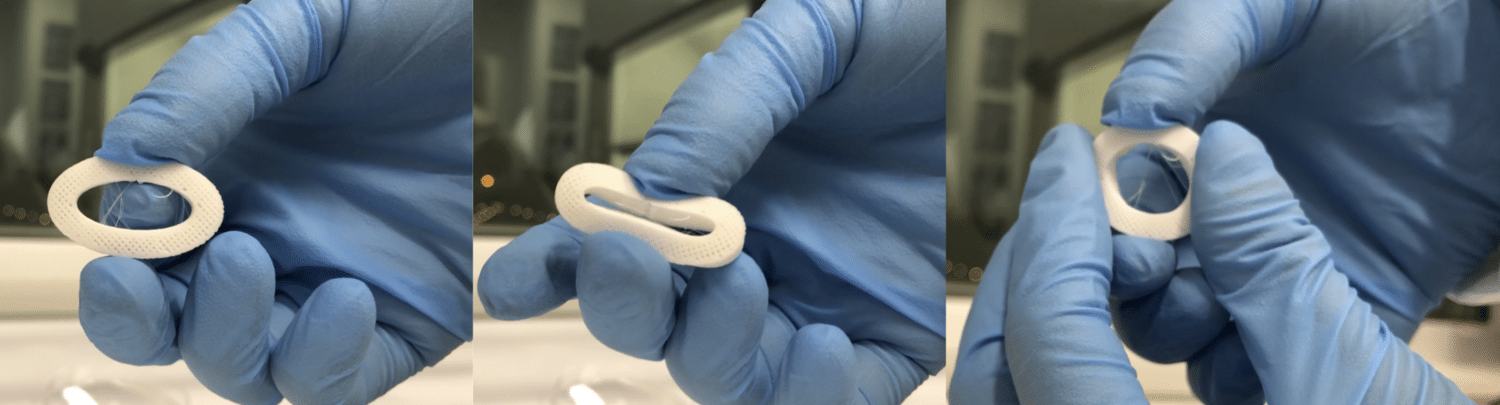

Bone tissue engineering is a field whose relevance is paramount, especially for the treatment of musculoskeletal-related disabilities. Failure of conventional methods to create physiologically relevant bone materials has prompted exploring several 3D-printing and additive manufacturing processes, including bioprinting, selective laser sintering, electrospinning and stereolithography. These technologies emerged in conjunction with new materials such as Hyperelastic Bone™, graphene and thermoplastics coupled with cell-laden hydrogels. This work will review these current state-of-the-art materials and technologies, their impact on advancements in bone tissue engineering and will highlight future considerations for the field.

In addition to reviewing bioinks for bone engineering, Pereira examines the different techniques that have emerged within the bone biofabrication field; 3D bioprinting, selective laser sintering (SLS), electrospinning and stereolithography.

Read on below to learn about the promising methods for bone engineering, where Pereira sees a need for innovation and why she is excited for the future of Hyperelastic Bone.