Allevi Blog

Allevi Author: BWH Proves Porous Bioink is Preferred

- Updated on February 20, 2020

We’re so excited to welcome the Yu Shrike Zhang lab from Brigham & Women’s Hospital to the Allevi Author Club! His new paper explores how porous is preferred when it comes to bioink composition. Read on to learn why:

3D bioprinting is an amazing technology which allows researchers to create custom cell-laden constructs that mimic the human body better than their 2D counterparts. Here at Allevi, our mission is to make it easy for scientists to replicate the body outside the body. Our community of users, composed of the leading minds in tissue engineering, are working on every type of tissue from the brain to bone.

Agnostic of tissue type, one of the most important aspects of 3d bioprinting is ensuring that your cells organize and proliferate as they would in your body. Bioinks provide cells with much-needed support that allows them to more easily organize into the geometries that they would in native tissue. However, if a bioink is too dense or too rigid, it can actually hinder the proliferation of cells and prevent them from performing their needed function.

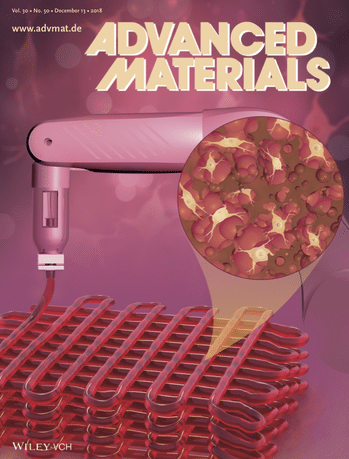

Our new #AlleviAuthors tackled this problem in their new paper titled “Aqueous Two‐Phase Emulsion Bioink‐Enabled 3D Bioprinting of Porous Hydrogels” and published in Advanced Materials.

By creating an aqueous bioink emulsion, the researchers were able to create a construct that is porous in composition while at the same time providing the rigidity needed in order to create 3D constructs. Their bioink is composed of cells mixed with GelMA and PEO which are immiscible materials – meaning that they do not mix in a homogenous manner. A classic example of immiscible liquids is oil and water. The fact that GelMA and PEO naturally repel each other means that small droplets of each material exist side by side within the bioink.

Using the Allevi 2 bioprinter, this bioink was bioprinted and crosslinked to form the desired geometry and rigidity of the tissue type that you are recreating. After the desired geometry has been achieved, you are then able to remove the PEO from the construct leaving small holes in the structure that allow cells to proliferate with greater ease.

The researchers tested their new method across 3 different cell lines and found that the porous 3D-bioprinted hydrogels showed enhanced cell viability and proliferation vs nonporous hydrogels. This new method means that researchers across any tissue type are now able to create porous-structures with higher cell viability. We’re excited to see the far-reaching effects of this method for our entire community of Allevi researchers!

Read on to learn more about their novel bioink and how to incorporate it into your research: https://onlinelibrary.wiley.com/doi/full/10.1002/adma.201805460